What happens when there is a sudden demand for a healthcare product, like alcohol-based sanitizers? Or when a consumer wellness company needs to expand its production capacity quickly? Chances are they will call Scapa Healthcare.

Scapa Healthcare is a trusted strategic outsourcing partner for leading MedTech companies in advanced wound care, consumer wellness, and medical device fixation. We collaborate with our healthcare customers to develop and manufacture innovative skin-friendly medical device fixation and skin care topical solutions to improve people’s lives.

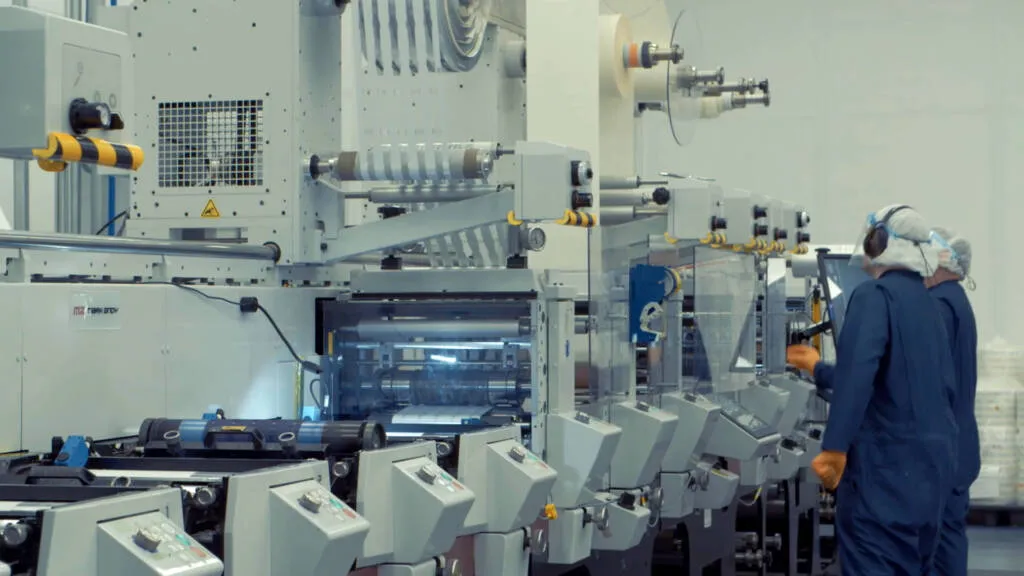

“Scapa Healthcare has the ability to work with technically challenging designs and requirements,” explained Lionel Bonte, Mativ’s President of Healthcare & Wellness, in an interview with Healthcare Everything Magazine. “We support the customer with prototypes and testing requirements, and once the design is approved, the operations and supply chain teams start working on sourcing material and validating the products.”

Meeting critical needs

Take, for example, the challenges faced by a leading provider of a critical hydrogel-based advanced wound dressing for life-threatening injuries. The provider was facing numerous supply chain and quality issues that were seriously impacting its ability to get its products to its customers. Back orders were starting to build up and became a huge pain point, until Mativ’s Scapa Healthcare team stepped in.

After discussing the requirements for the customer’s proprietary wound care dressing design, the Scapa Healthcare team quickly developed a new and efficient manufacturing process. Our engineers created prototypes ahead of ordering new raw materials, which allowed the customer to preview modifications and act quickly to approve the change. The Scapa Healthcare team’s regulatory experience meant they were able to accommodate the customer’s specific regulatory requirements to sell the dressings in international markets.

Reducing risks

Scapa Healthcare’s wide range of manufacturing solutions also includes gamma irradiation services. No, it won’t turn you into a giant green superhero, but it will sterilize medical tools and equipment. “Improperly sterilized medical devices can pose a significant risk to patients,” explained April Ambridge, Head of Quality at Scapa Healthcare. “Our Gargrave site is home to two microbiology laboratories – plus an on-site gamma irradiation plant – that support customers with sterility testing and validation of medical equipment.”

Scapa Healthcare’s sterilization offerings, which include a training program for healthcare companies, are vital for customers manufacturing sterile medical devices. The arduous process of designing, developing, and/or manufacturing a sterile medical device doesn’t mean anything unless the creator can ultimately demonstrate that the product is sterile at the end of development. “At a very high level, we are establishing a customer’s minimum necessary dose to achieve sterility through our testing,” April continued. “We do dose setting and substantiation studies according to ISO 11137 standards which govern radiation sterilization processes for medical device manufacturers.”

Improving patient health and comfort

Some medical devices, like ostomy products or pulse oximeters, are only effective when they adhere to the skin. “Hydrocolloids are a skin contact adhesive that contain gel-forming agents,” explained Pranabes Pramanik, Senior Principal Scientist and R&D Manager for Scapa Healthcare. Hydrocolloid technology gently and securely adheres to the skin and absorbs body fluids, which helps to improve patient health and comfort. For this reason, “hydrocolloids are used in many ostomy applications for the fixation of the bag,” continued Pranabes. “Hydrocolloids can also be used in diabetes care with patches on infusion lines connected to an insulin pump and glucose monitoring devices.”

Beyond that, Scapa Healthcare’s hydrocolloid technology may also be found in a broad array of consumer wellness products, like skin patches for acne and foot care. These hydrocolloid-based treatments facilitate healing, seal out contaminants, and can be worn for extended periods.

“From hospital devices to retail-grade medical products, Scapa Healthcare offers turn-key packaging solutions for diverse medical markets,” Lionel Bonte concluded. “Our highly qualified technical experts and state-of-the-art global footprint enable us to offer customers the whole spectrum of development and production services from inception through to market delivery.”

To learn more about Scapa Healthcare, visit their website or follow them on LinkedIn. Visit our solutions page to learn more about the Mativ family of brands.